Malabou Testing & Services

Advanced Testing & Managed Testing Programmes

Why Malabou?

Because testing alone is not the problem — managing complex, long-duration testing programmes is.

Most laboratories focus on individual tests.

Consultants advise but don’t execute.

OEM test houses are often constrained by internal priorities and limited scope.

Malabou – Testing & Services operates as your technical extension on the ground. We combine advanced materials testing with fully managed testing programmes, providing independent engineering oversight, accredited results, and a single point of technical accountability — while leveraging a distributed network of ISO/IEC 17025-accredited laboratories across India.

Malabou’s Advantage – Managed, Accredited, On-the-Ground

Through our ISO/IEC 17025 laboratory network, Malabou enables:

Parallel testing across multiple laboratories to compress programme timelines

Parallel testing across multiple laboratories to compress programme timelines

Access to specialised test rigs without capital investment

Access to specialised test rigs without capital investment

ISO/IEC 17025 traceability supporting qualification and compliance

ISO/IEC 17025 traceability supporting qualification and compliance

Scalable capacity for development, validation, and production support

Scalable capacity for development, validation, and production support

Seamless integration with metallurgical analysis and failure investigation

Seamless integration with metallurgical analysis and failure investigation

This networked, managed approach reduces cost, shortens validation cycles, and accelerates adoption of new materials, coatings, and manufacturing processes.

Managed Testing Programmes

Malabou manages complete testing programmes for:

OEMs

OEMs

Industrial asset owners

Industrial asset owners

Consulting engineers

Consulting engineers

Researchers and technology developers

Researchers and technology developers

Clients benefit from clearly defined scopes, consolidated reporting, and direct metallurgical and engineering oversight from test initiation through to final results — without the burden of coordinating multiple laboratories, time zones, or technical interfaces.

On-the-Ground Technical Oversight

Malabou’s physical presence within partner laboratories allows us to:

Verify test methodologies and compliance with applicable standards

Verify test methodologies and compliance with applicable standards

Review sample preparation and test execution

Review sample preparation and test execution

Engage directly with laboratory metallurgists and technicians

Engage directly with laboratory metallurgists and technicians

Ensure results are technically robust, traceable, and globally recognised

Ensure results are technically robust, traceable, and globally recognised

Malabou governs the entire process, while maintaining independence, accreditation, and technical rigour.

Advanced Materials Testing Capabilities

FRAS (Flame Retardant & Anti-Static Testing)

Verification of flame retardant and anti-static performance for polymer and elastomer components used in safety-critical and hazardous environments, including mining, materials handling, and industrial applications.

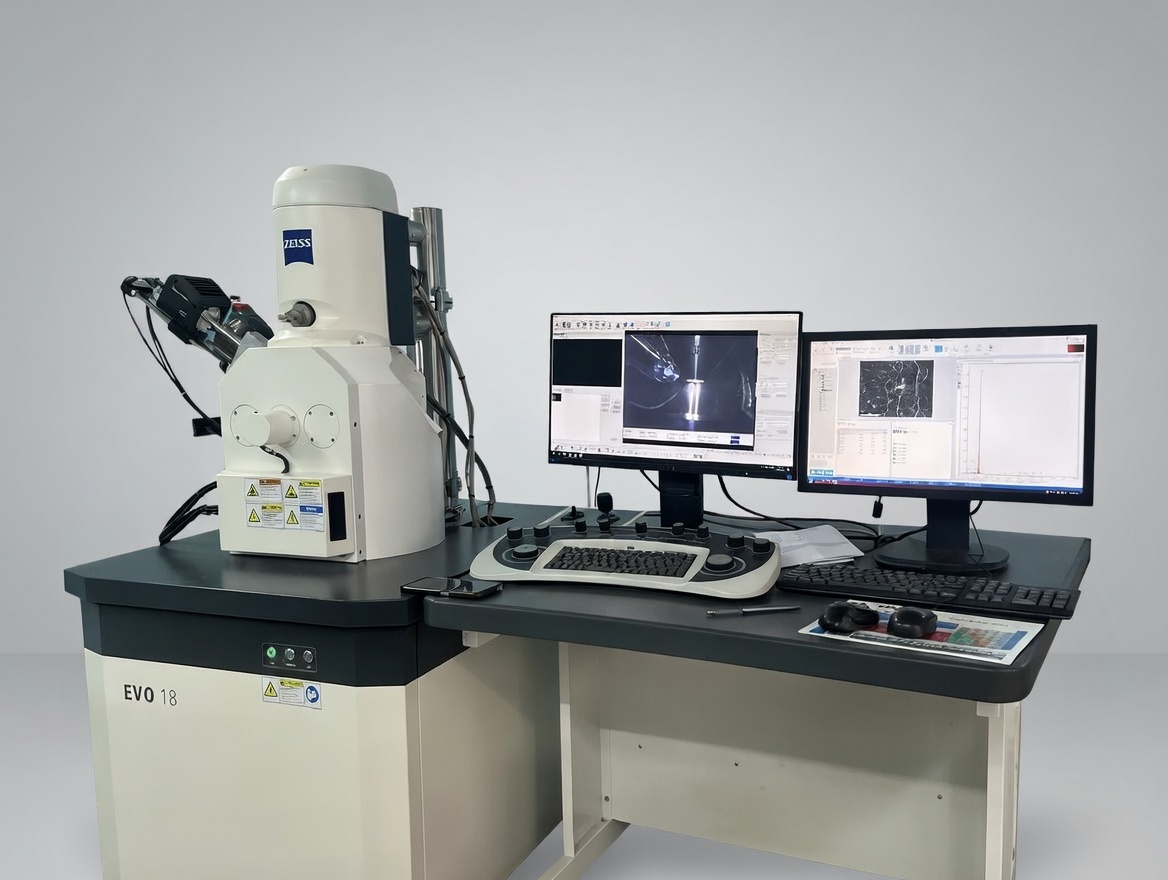

SEM & EDAX

Scanning Electron Microscopy (SEM) and Energy Dispersive X-ray Analysis (EDAX) for detailed characterisation of:

Microstructure and phase distribution

Microstructure and phase distribution

Fracture features and crack morphology

Fracture features and crack morphology

Inclusions, contamination, and defects

Inclusions, contamination, and defects

Qualitative and semi-quantitative elemental composition

Qualitative and semi-quantitative elemental composition

Failure Analysis – SEM Fractography

High-resolution fracture surface analysis to identify crack initiation, propagation mechanisms, and final fracture modes, supporting root-cause failure investigations and design or process improvement

Extended-Time Material Testing

Extended-time material testing answers a fundamental engineering question:

“What actually happens to this material after months or years in service?”

Unlike short-duration mechanical tests, extended testing captures time-dependent degradation mechanisms such as fatigue, creep, rupture, corrosion, oxidation, and environmental ageing — mechanisms that often govern real-world performance and failure.

Extended-time testing supports:

Material qualification and benchmarking

Material qualification and benchmarking

New process and surface treatment validation

New process and surface treatment validation

Life prediction and remaining-life assessment

Life prediction and remaining-life assessment

Risk reduction in demanding service environments

Risk reduction in demanding service environments

Extended-Time Testing Capabilities

Fatigue Testing

High-cycle fatigue (HCF)

High-cycle fatigue (HCF)

Low-cycle fatigue (LCF)

Low-cycle fatigue (LCF)

Axial fatigue testing

Axial fatigue testing

Flexural (bending) fatigue testing

Flexural (bending) fatigue testing

Torsional fatigue testing

Torsional fatigue testing

Radial fatigue testing

Radial fatigue testing

High-temperature fatigue testing

High-temperature fatigue testing

Creep & Stress Rupture Testing

Constant-load creep testing

Constant-load creep testing

Creep-rupture and stress-rupture life assessment

Creep-rupture and stress-rupture life assessment

Elevated-Temperature Mechanical Testing & Thermal Ageing

Mechanical testing at elevated temperature

Mechanical testing at elevated temperature

Long-term thermal exposure

Long-term thermal exposure

Microstructural stability assessment

Microstructural stability assessment

Environmental & Weathering Exposure

Accelerated UV exposure

Accelerated UV exposure

Humidity and condensation exposure

Humidity and condensation exposure

Thermal cycling and environmental ageing

Thermal cycling and environmental ageing

Corrosion & Oxidation Testing

Long-term oxidation behaviour

Long-term oxidation behaviour

General and localised corrosion assessment

General and localised corrosion assessment

Salt Spray Testing

Neutral Salt Spray (NSS)

Neutral Salt Spray (NSS)

Acetic Acid Salt Spray (ASS)

Acetic Acid Salt Spray (ASS)

Copper-Accelerated Acetic Acid Salt Spray (CASS)

Copper-Accelerated Acetic Acid Salt Spray (CASS)

Applicable Standards (Indicative)

ASTM E466 – Force-Controlled Constant Amplitude Axial Fatigue Tests

ASTM E466 – Force-Controlled Constant Amplitude Axial Fatigue Tests

ASTM E606 / E606M – Strain-Controlled Fatigue Testing

ASTM E606 / E606M – Strain-Controlled Fatigue Testing

ASTM E139 – Creep, Creep-Rupture, and Stress-Rupture Testing

ASTM E139 – Creep, Creep-Rupture, and Stress-Rupture Testing

ASTM B117 – Salt Spray (Fog) Testing

ASTM B117 – Salt Spray (Fog) Testing

ASTM G85 – Modified Salt Spray Testing

ASTM G85 – Modified Salt Spray Testing

ISO 1099 – Axial Force-Controlled Fatigue Testing

ISO 1099 – Axial Force-Controlled Fatigue Testing

ISO 204 – Uninterrupted Creep Testing

ISO 204 – Uninterrupted Creep Testing

ISO 9227 – Corrosion Tests in Artificial Atmospheres (Salt Spray)

ISO 9227 – Corrosion Tests in Artificial Atmospheres (Salt Spray)

EN 10291 – Long-Term Creep Testing of Metallic Materials

EN 10291 – Long-Term Creep Testing of Metallic Materials

AS/NZS 1580 – Paints and Related Materials – Methods of Test

AS/NZS 1580 – Paints and Related Materials – Methods of Test

Standards Disclaimer

The standards listed above are indicative and representative of commonly applied test methods. Testing may be performed to equivalent ASTM, ISO, EN, AS/NZS, or customer-specific specifications as required by project scope, material type, and regulatory or contractual requirements.